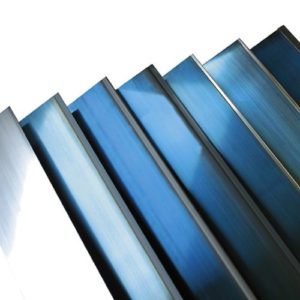

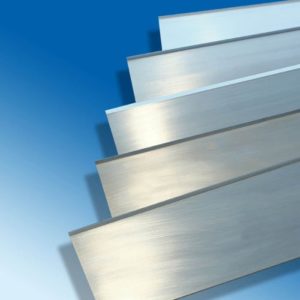

Headbox Sheets- Lexan and CPVC

BTG headbox sheets improve the operations of the paper machine. The headbox nozzle is a critical area in developing high-quality paper parameters. Therefore, our unique manufacturing process produces sheets of highest quality.

We offer the smoothest polycarbonate surface in the industry through a special finishing process that provides an extremely smooth finished surface. In addition, we can apply a surface modifier to enhance the material’s release aspect -promoting even cleaner operating sheets.

The sheet tip is the primary controlling item in developing the nozzle flow characteristics. Sheets come in various tip designs including: “Blunt”, “Tapered” and “Serrated”.

Two different types of material are available: Polycarbonate and CPVC

BTG uses a unique and proprietary flow modeling technique we refer to as “Energy Expansion” calculations. This method allows us to easily review the effect that specific sheet designs have on the flow inside of the headbox nozzle while also being able to categorize the fiber activity levels present. In turn we can then engineer sheet designs to allow the headbox to operate in its ‘sweet spot’. So if you want to improve headbox sheet profile uniformity give a BTG expert a call and let us show you how!