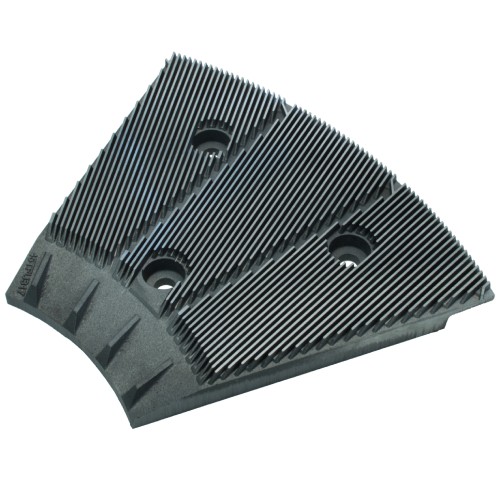

For stock preparation, our continuous improvement approach offers custom solutions to optimize fiber development and specific energy consumption in low consistency refiner plate applications.

Recent advancements in casting and metallurgical technology have resulted in lower energy, reduced furnish costs and faster paper machine speeds. One of our engineers can audit your system and recommend a low consistency refiner plate design to meet your paper machine productivity goals.

J&L’s “Six Step Refiner Optimization Process” (shown below right) helps to identify your mill’s most challenging situations and helps create custom solutions. We will enhance your refiner productivity by sharing application expertise while matching refining parameters to achieve pulp/paper/board properties through plate design and alloy technology.

Plate design techniques are carefully crafted to:

- Reduce Bar Breakage

- Reduce Fiber Plugging

- Reduce Pulp & Paper Mill Shive Levels

- Reduce Furnish Costs

- Reduce Energy Consumption

- Enhance Plate Life

Together, the steps in our proven process will result in:

- Increased Plate Life

- Reduced Plate Breakage

- Reduced Plate Plugging Problems

- Improved Pulp Strength or Quality

- Reduced Sheet Breaks

- Lower Shive Levels

- Reduced Fines

- Lower Furnish Costs

- Increased Refining Capacity

- Energy Savings

- Higher Production Rates